Coordination of Large Robot Teams in Automated Warehouses

Today, in automated warehouses, mobile robots already autonomously move inventory pods or flat packages from one location to another. Finding low-cost paths for the robots in real-time is essential for the effectiveness of such systems. Multi-Agent Path Finding (MAPF) technologies (see more details in our research on Foundations of MAPF) provide a promising solution for coordinating these robots. However, to apply MAPF in this scenario, we need to address four challenges, namely how to assign tasks to agents, how to decompose the lifelong problem to one-shot MAPF problems and solve it efficiently, how to handle robot dynamics and uncertainties during execution, and how to design the warehouse layouts.

Combined Task and Path Planning

Automated warehousing systems need to continually assign delivery tasks and collision-free paths to robots in an online manner. Traditional task assignment algorithms ignore collisions among agents, which can generate task assignments that eventually lead to costly collision-free paths or even no collision-free paths. We develop various of combined task and path planning algorithms with different properties (e.g., optimal, complete, capable of handling time-window constraints, etc.) that suit for different scenarios.

Relevant publications: [1] Decoupled online task assignment and path planning, [2] Decoupled offline task assignment and path planning, [3] CBS-based optimal task and path planning, [4] LNS-based task and path planning, [5] Deadline-aware task and path planning, and [6] column generation for tasks with time windows.

Scalability and Solution Quality

The principled way of solving this challenge is to develop more efficient and effective MAPF algorithms. More details can be found in our research on Foundations of MAPF.

The principled way of solving this challenge is to develop more efficient and effective MAPF algorithms. More details can be found in our research on Foundations of MAPF.

Additionally, MAPF is only the “one-shot” variant of the actual problem in the automated warehouses. Typically, after an agent reaches its goal location, it does not stop and wait there forever, which requires us to call MAPF solvers periodically to plan and replan in an online manner. This is a challenge but also an important property that we can make use of when we develop MAPF algorithms.

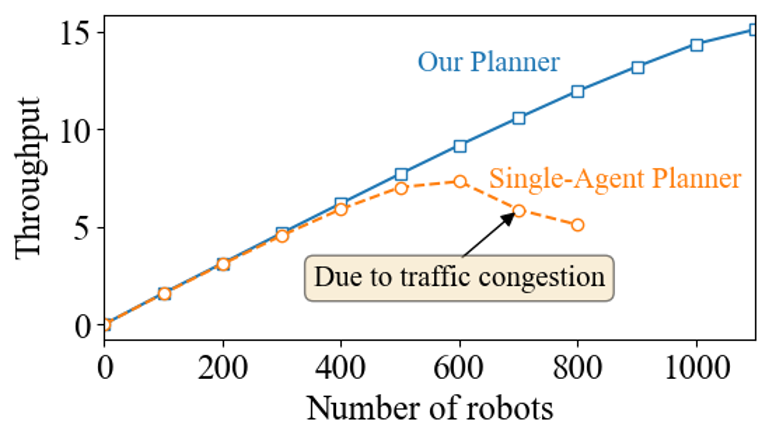

Highlights: The RHCR algorithm proposed in [1] can produce high-quality solutions for 1,000 agents (= 38.9% of the empty cells on the map) for simulated warehouse instances. The videos shown at the top of the page show the performance of 800 agents on the same map with traditional single-agent solver and RHCR, and the figure on the left summarizes the throughput results with different numbers of agents.

We recently developed a complex planner, summarized in [2], that won a competition sponsored by Amazon Robotics. This planner can coordinate up to 10,000 agents with planning times under a second. The two videos below show two challenging instances from the competition. A follow-up work [3] further improved the planner through imitation learning.

Relevant publications: [1] rolling-horizon collision resolution, [2] Winning solution for the 2023 League of Robot Runners, [3] Imitation learning for 10k agents, and [4] Traffic flow optimization.

Combined Planning and Execution

MAPF algorithms can find high-quality collision-free paths for automated warehousing under simplified assumptions about the robot dynamics. However, these simplifying assumptions pose challenging implementational issues since the robots cannot follow the paths precisely. Therefore, some recent research has focused on more complicated MAPF models to close the gap. But, robot dynamics are complex and almost impossible to be modeled perfectly. We therefore study how to combine (task and path) planning with execution control from three perspectives, namely what planning model works best in terms of maximizing final throughput and minimizing planning time, how we overlap planning and execution to avoid robot idle time during replanning, and how we design effective execution policies that is robust to unmodeled robot dynamics and uncertainty.

MAPF algorithms can find high-quality collision-free paths for automated warehousing under simplified assumptions about the robot dynamics. However, these simplifying assumptions pose challenging implementational issues since the robots cannot follow the paths precisely. Therefore, some recent research has focused on more complicated MAPF models to close the gap. But, robot dynamics are complex and almost impossible to be modeled perfectly. We therefore study how to combine (task and path) planning with execution control from three perspectives, namely what planning model works best in terms of maximizing final throughput and minimizing planning time, how we overlap planning and execution to avoid robot idle time during replanning, and how we design effective execution policies that is robust to unmodeled robot dynamics and uncertainty.

Relevant publications: [1] Different MAPF models for warehouse robots, [2] Online re-scheduling of agents’ execution, [3] Offline re-scheduling of agents’ execution, and [4] A motion planning algorithm designed for Differential drive robots.

Environment Optimization for Multi-Robot Coordination

The environment that the robots navigate in significantly influence their coordination efficiency and effectiveness. We study how to design good warehouse layouts to improve the coordination efficiency. We also study how to optimize virtual environments, such as guidance graphs, for the robots to enhance their performance.

Relevant publications: [1] Direct layout optimization, [2] Optimizing a layout generator, [3] Offline guidance graph optimization, [4] Online guidance graph optimization, and [5] Dataset and analysis for MAPF in 3D warehouses.